If you are looking for a way to advance your beverage system, you may want to consider the addition of spray deaeration. This type of advanced technology can improve the final product while also offering a few other benefits. It has a goal of reducing entrained O2 and other gasses that are in the process water. That may not seem like a big deal, but this investment can significantly change the way you operate your organization and the product quality that you get.

What Are the Advantages?

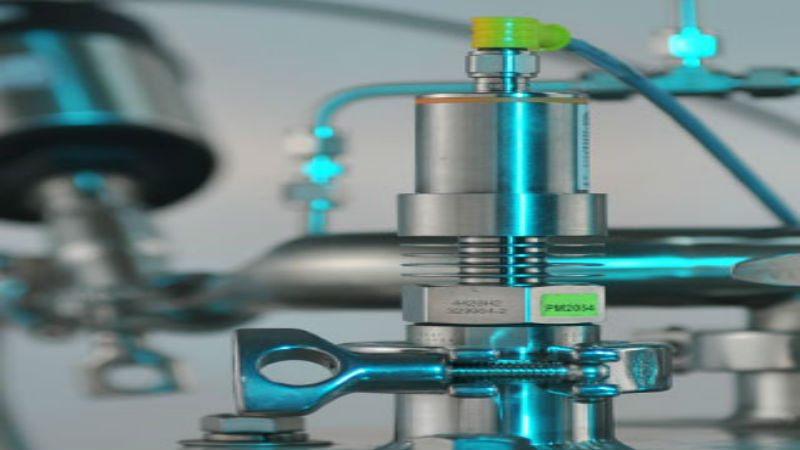

When you incorporate spray deaeration into your system, you gain a tighter process. That is, you have the ability to use instruments that allow you to have a better level of control over the entire process. This allows you to make tweaks and to gather data about your product at any level of the process. Ultimately, it lets you make adjustments to create a better product. In addition to this, this type of equipment also helps to reduce the foaming of your product. As a result of that, it can help to extend the shelf life of your product, meaning there is less product wasted overall.

Consider These Benefits, Too

In addition to this, some of the best systems are also maintenance free systems. They are very easy to use, easy to teach, and reliable in the long term. They can also handle a large volume of product without any failure of quality.

All of these features of spray deaeration can be beneficial to nearly any beverage production. It is always important to choose a system that is highly reliable and designed to incorporate the latest technology. Compare the options available to you today before making any purchase. It is worth investing a bit more into these cutting edge tools.