If you’re a business owner in Minnesota, you may be looking for ways to cut costs and improve efficiency. One option that you may not have considered is part-kitting. Part-kitting is a process where individual items or components are put together into kits that can then be sold as a single unit. This process can save your business time and money, and it can also help improve customer satisfaction. In this article, we will discuss the benefits of part-kitting in Minnesota and how your business can take advantage of this process.

It Can Streamline Your Production Process

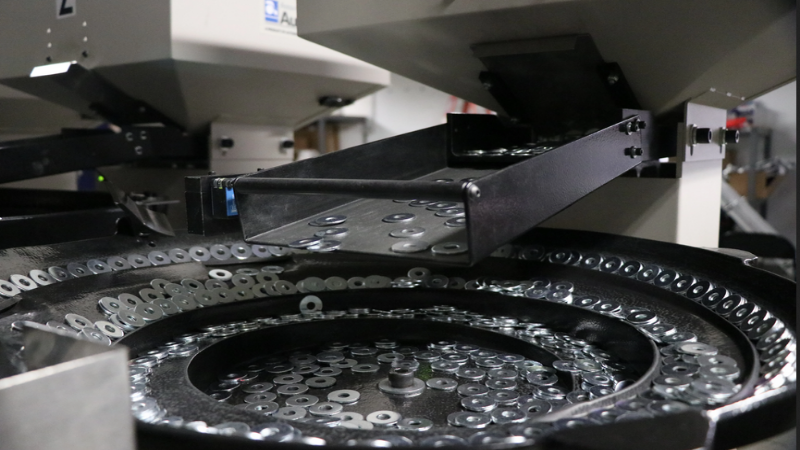

Having to source multiple kitting parts for assembly is both challenging and time-consuming when you’re on your own. But you need those kits to be sold with your products, so what can you do? This is where part-kitting in Minnesota comes in. Part kitting can streamline your production process by allowing you to source all of the components for a kit from one supplier. This can save you a significant amount of time and money, as you won’t have to worry about tracking down multiple suppliers for each component.

It Can Simplify Your Inventory

When parts for your kits are sourced individually, each part within that kit comes with its own unique identifying code, which goes into your inventory system. These parts can really add up and create a lot of clutter in your inventory. Part-kitting in Minnesota can simplify your inventory by reducing the number of unique codes that you have to track. Instead of tracking each individual part, you’ll just need to track the kit as a whole. This can make it much easier to keep track of your inventory and ensure that you always have the kits that you need.