In the aerospace industry, there is no room for mistakes. It is a high-stakes world where precision aerospace components are not just important, but they are also the building blocks of safety and efficiency.

The Importance of Precision

Every component in an aerospace vehicle plays a critical role in its operation. Each part must be manufactured with utmost precision, from tiny screws that hold panels together to large turbine blades that power engines. A minor deviation can lead to catastrophic failures, endangering lives and causing significant financial losses.

Precision extends beyond just the physical dimensions of a component. The composition encompasses the choice of materials, their capacity to endure temperature and pressure, and their resilience against wear and tear. These demanding criteria can only be met by employing meticulously crafted materials of the utmost quality.

The Role of Advanced Manufacturing Technologies

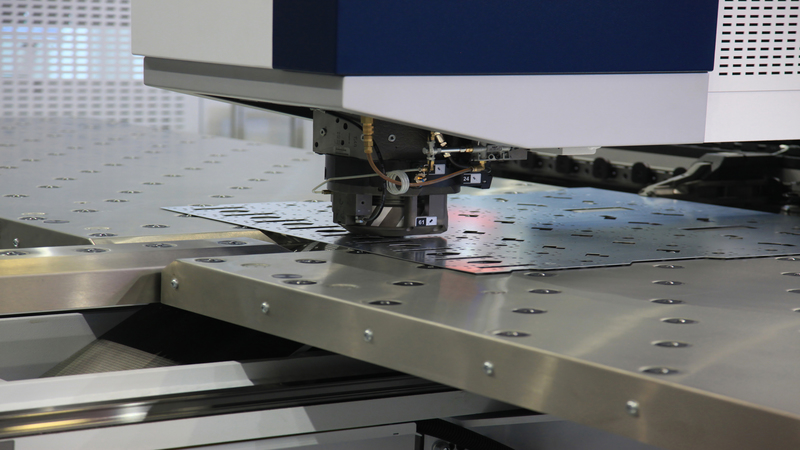

Advanced manufacturing technologies have revolutionized the production of precision aerospace components. Techniques such as 3D printing, CNC machining, and composite manufacturing enable faster, more cost-effective, and highly accurate production of components. These advancements have significantly enhanced the quality and efficiency of aerospace manufacturing processes.

These advanced technologies also empower the fabrication of intricate components that were once deemed unachievable, thereby unlocking boundless prospects in the realm of aerospace design. Lightweight yet strong materials, intricate designs, and increased fuel efficiency are now within reach, thanks to these advanced techniques.

Precision aerospace components are the unsung heroes of the aerospace industry. They are responsible for ensuring the safety, efficiency, and success of every mission. As technology continues to evolve, we can anticipate even greater advancements in the precision and performance of these crucial components.