Plastic is a common component of many of our everyday items. It forms the basis of everything from toothbrush handles to chairs and automotive parts. Several processes exist to produce these plastic parts. Plastic molding services in common production usage is plastic extrusion. It is responsible for producing components for a variety of applications.

Plastic Extrusion

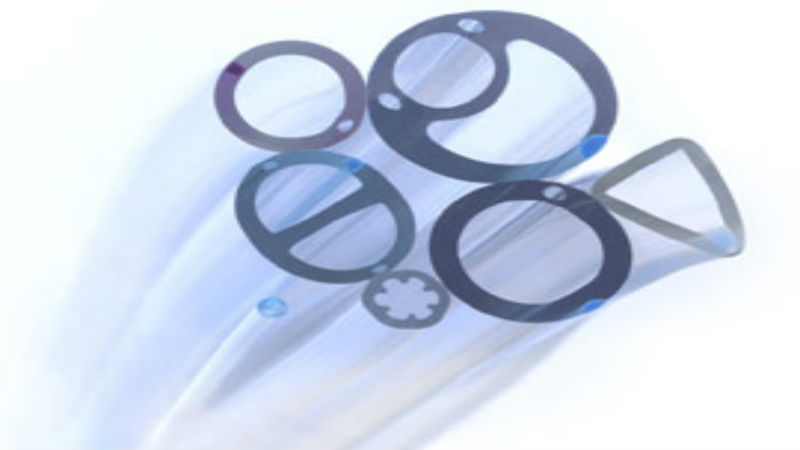

This process takes thermoplastic, melts it and pushes it through a die into a specific form with a continuous profile or fixed cross shape. The plastic cools and hardens into this shape. The process can utilize different types of thermoplastics to produce the desired results and qualities for the application. Plastic molding services may include additives to improve certain characteristics or add color.

Applications for Plastic molding services

Plastic is popular for the production of many common essentials of our daily lives. Among the most common products plastic extrusion produces are:

• Automotive trim: This is the preferred method of creating this product

• Decks and deck railings: Plastic extrusion provides these and similar products, e.g., outdoor furniture with weatherproof, splinter-free qualities

• Fencing: Easy to form and virtually maintenance free

• Pipe/tubing: This hollow product is in demand for large sewage and water pipes and smaller medical tubes and drinking straws

• Plastic films and sheeting: Can act as replacements for glass and in such uses as blister packs and in other retail package formats

• Vinyl Siding: This results from employing plastic extrusion

• Weatherstripping: Plastic extraction reproduces this product easily and swiftly

• Window frames: This process helps reduce overall costs for windows while decreasing energy usage. Today, they are both durable and attractive

• Wire insulation: Both electrical and non-electrical wires receive insulation created through plastic extrusion to provide protection against various corrosive elements, reduce abrasion and/or deliver robust electrical insulation attributes

When it comes to plastic molding services, some companies request plastic extrusion. It is capable of producing a great many applications quickly efficiently and accurately.