For many industry workers, plastic components are integral. If you’re a staple in the electronics, instrumental, or medical industries, it’s probably safe to assume you rely on sturdy, well-manufactured plastic pieces. Choosing a reliable machining company guarantees quick turnaround, personalized support, cost-effective rates, and long-lasting solutions. Seasoned plastic machining professionals can create new or replacement pieces to suit your specifications. Trusted companies utilize all of the best materials and latest machining technology to create clear, heavy-duty components.

Critical in Various Industries

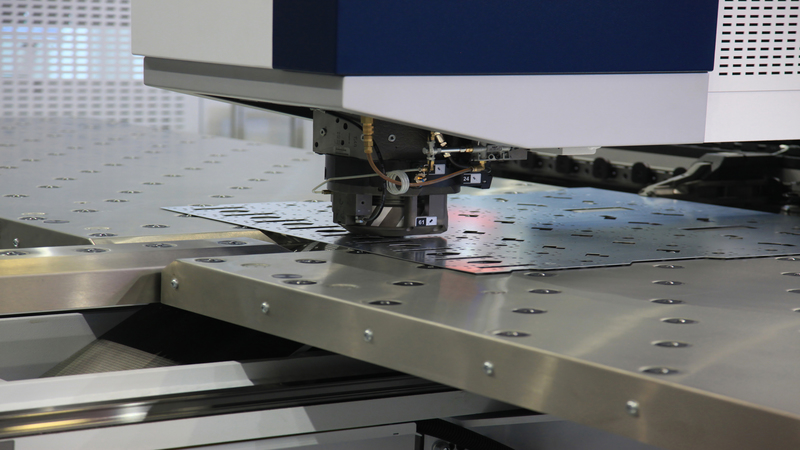

Machining plastic is a complex process that involves utilizing a variety of tools and methods to produce to an expertly-crafted component. There are a multitude of methods employed by professionals, based on their clients’ needs. For instance, professionals can quickly manufacture complex plastic pieces through plastic milling or plastic CNC machining – which are just two of many options. In many industries, plastic is preferred over other types of materials because it’s easy to mold. Additionally, several machining methods are available – which ensures the right end-products are created.

Advantages of Plastic Fabrication

Regardless of order size, machined plastic components are normally highly available. This makes it a great deal more practical than metal components in terms of cost. Plastic is tough, readily available, and versatile – reducing machine costs and the need for recurring engineering. Also, plastic machining simplifies the process of prototyping. Not only does the process produce fast product prototypes, it also removes the costs associated with tooling. An experienced machining company can help you fabricated the ideal prototype, and replicate it using high quality plastic, top-notch equipment, and innovative machining technology.

Importance of Machining Skill

To receive the highest quality end-products, it’s important to choose a company that knows the ins and outs of plastic and acrylic machining. They’ll have the tools and experience to simplify everything from creating a prototype, to CNC fabricating, to vapor or flame polishing. Machining professionals work hard to meet clients’ needs, while doing everything possible to avoid stress cracking, blurriness, and rough surfaces. Some experts can also handle orders that demand tight tolerances. Micro machining services can be hard to locate. However, highly trained professionals use a combination of equipment and skill to manufacture small pieces.

PEP Connecticut Plastics has offered professional plastic machining and micro plastic machining services since 1980. For more information on their capabilities, visit Pepctplastics.com.